Lower Power Industrial PCs for Remote Data Acquisition

Lower Power Industrial PCs for Remote Data Acquisition

In today’s industrial landscape, remote data acquisition (DAQ) is a cornerstone for process optimization, predictive maintenance, and informed decision-making.

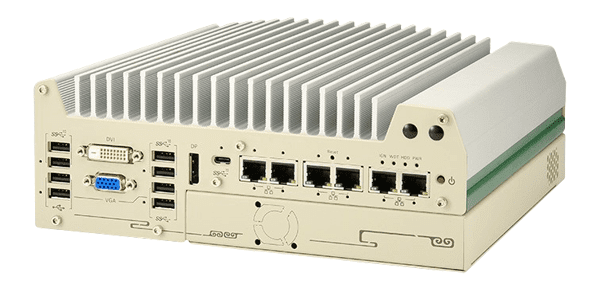

Industrial PCs (IPCs) play a vital role in this process by collecting data from sensors, instruments, and other devices in remote locations and transmitting it for central processing and analysis.

However, with growing numbers of data acquisition points spread across wider areas, power consumption becomes a critical consideration for IT professionals.

In today’s industrial landscape, remote data acquisition (DAQ) is a cornerstone for process optimization, predictive maintenance, and informed decision-making.

Industrial PCs (IPCs) play a vital role in this process by collecting data from sensors, instruments, and other devices in remote locations and transmitting it for central processing and analysis.

However, with growing numbers of data acquisition points spread across wider areas, power consumption becomes a critical consideration for IT professionals.

Lower power industrial PCs offer a compelling solution for remote data acquisition applications

Reduced Energy Costs: Lower power consumption translates directly to lower energy costs. This is particularly significant for deployments with a large number of remote data acquisition units.

Simplified Power Infrastructure: Lower power requirements often allow for the use of smaller power supplies and lighter gauge cabling, simplifying infrastructure needs and reducing overall installation costs.

Improved Reliability in Remote Locations: In remote locations, consistent access to reliable power can be a challenge. Lower power industrial PCs are better suited for deployment with backup batteries or solar power solutions.

Reduced Heat Generation: The fanless design of many low-power IPCs eliminates moving parts and reduces heat generation. This translates into improved reliability and lower maintenance requirements, especially in harsh industrial environments.

Things to Consider When Choosing Lower Power Industrial PCs for Remote DAQ

Here are some key factors to consider when selecting low-power industrial PCs for your remote DAQ application:

Processing Power: The processing power required depends on the complexity of the data acquisition tasks. Simple data logging may not require a powerful processor, while real-time data analysis might necessitate a more robust CPU.

Connectivity Options: Ensure the IPC has the necessary ports to connect to your sensors and communication networks, such as Ethernet, Wi-Fi, cellular, or serial communication ports.

Operating Temperature Range: Industrial environments can experience extreme temperatures. Choose an IPC with an operating temperature range suitable for your deployment location.

Data Security: Make sure the IPC offers robust security features to safeguard sensitive data collected from remote locations.

Remote Management Capabilities: Remote manageability features allow for easy configuration, troubleshooting, and updates of the IPCs deployed in remote locations.

Industrial PC: Your Partner in Remote Data Acquisition

Industrial PC offers a comprehensive selection of industrial PCs, including a wide range of lower power options suitable for remote DAQ applications. Our team of experts can help you select the ideal IPC to meet your specific needs and budget.

Contact Industrial PC today to discuss your remote DAQ requirements and get a quote. We’ll be happy to guide you in selecting the most efficient and reliable low-power industrial PC solution for your application.

TELL US YOUR PC REQUIREMENTS & GET A QUOTE:

Trending Most Popular Industrial Computers

TELL US YOUR PC REQUIREMENTS

and we’ll give you your options and price:

TIP: When building your quote below, each section allows you to select one option, multiple options, or no option if you’re unsure. Fill out as little or as much information as you know and we’ll take it from there!

BUILD YOUR EASY PC QUOTE:

Your selections

Trusted by