The Ultimate Guide to Choosing the Right Industrial Computer

The Ultimate Guide to Choosing the Right Industrial Computer

by Industrial PC ™

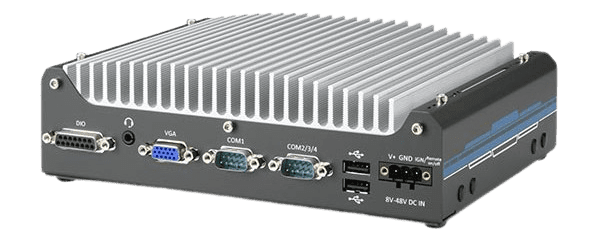

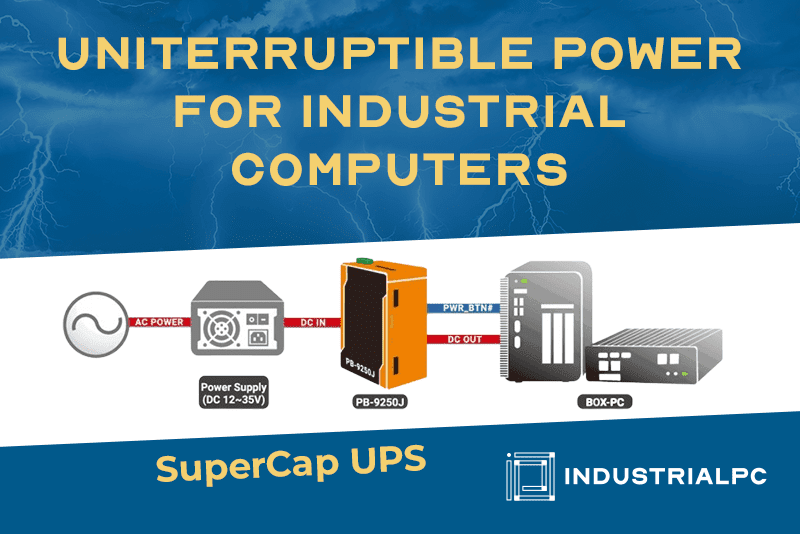

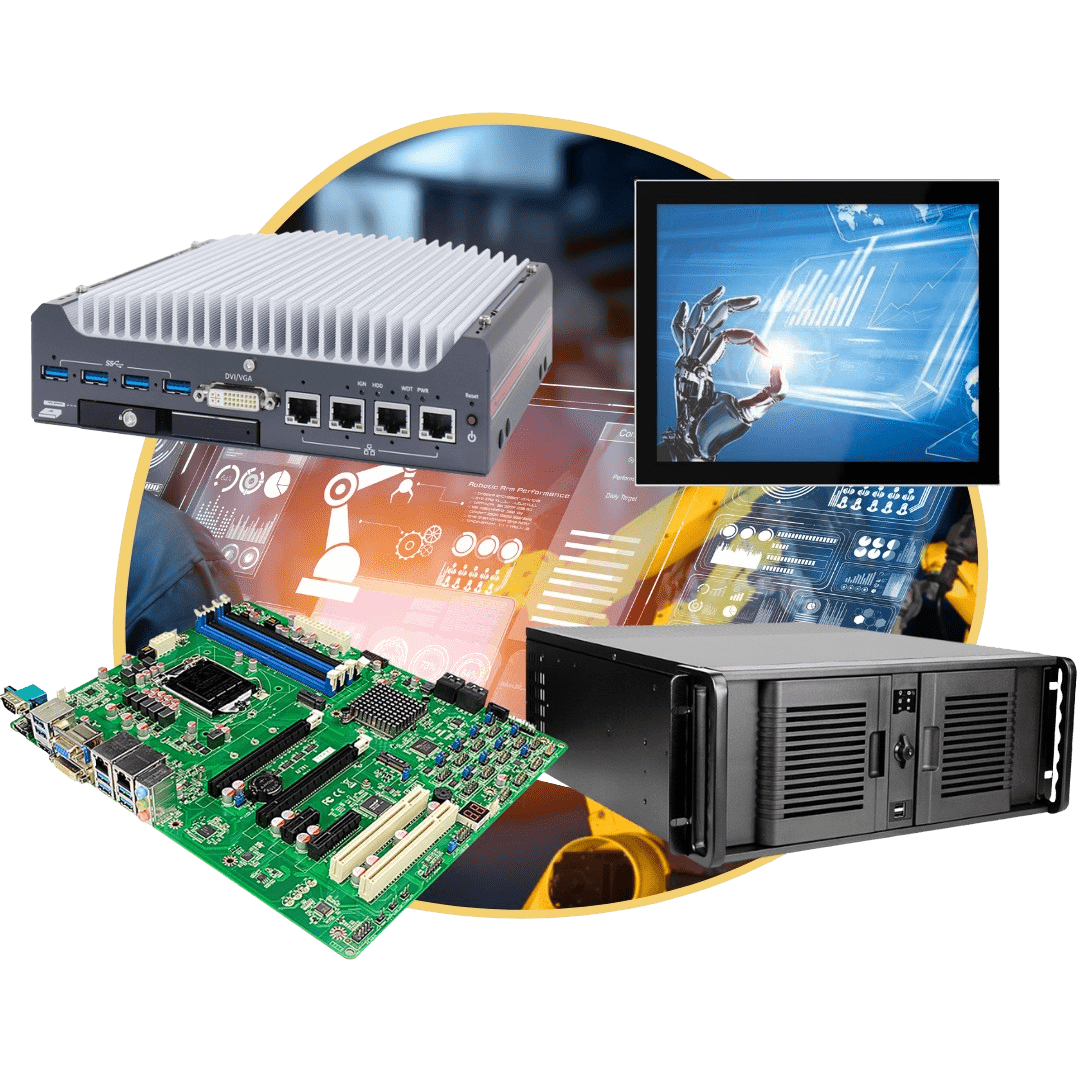

Industrial computers are specialized computing systems designed to operate in harsh environments that are not suitable for consumer-grade computers.

They are used in a wide range of industries, including manufacturing, oil and gas, transportation, and healthcare, to name a few. Industrial computers must be able to withstand extreme temperatures, vibration, dust, and humidity, among other factors.

Choosing the right industrial computer can be a daunting task, as there are numerous options available in the market.

In this guide, we will discuss the different types of industrial computers, their use cases, and the factors to consider when choosing the right industrial computer.

Types of Industrial Computers

USE CASES FOR INDUSTRIAL COMPUTERS

USE CASES FOR INDUSTRIAL COMPUTERS

Are you powering digital signage, in-vehicle computers, manufacturing…or something else? Shop fanless industrial computers by application below.

Factors to Consider When Choosing an Industrial Embedded Computer:

Industrial PC offers embedded computers with a range of expansion options, including support for additional memory, storage, and peripherals. Many of these systems also support expansion modules and daughterboards, allowing for additional customization.

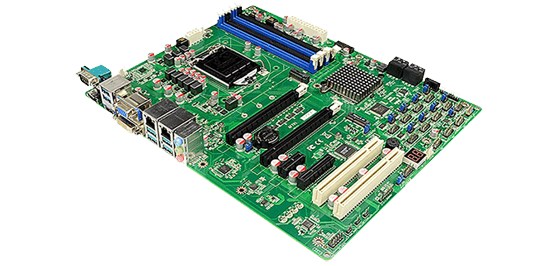

Factors to Consider When Choosing an Industrial Rackmount Computer:

Industrial PC offers a range of rackmount computers with varying form factors, performance levels, connectivity options, expansion options, cooling solutions, reliability features, and manageability features. These systems are designed to deliver high-performance computing in a standard 19-inch server rack, making them ideal for use in data center environments, server rooms, and other critical applications.

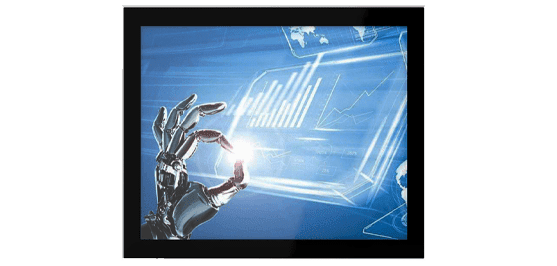

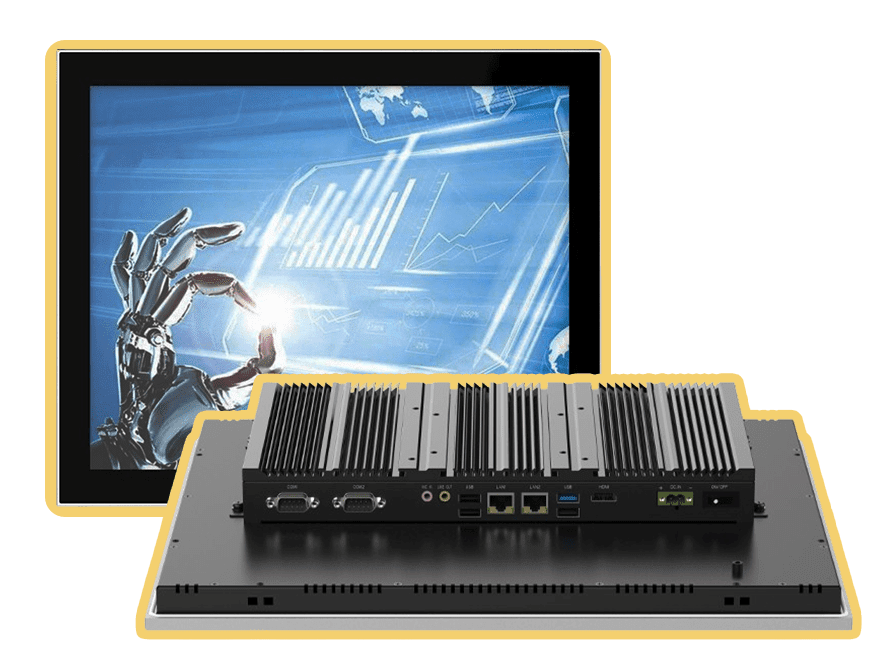

Factors to Consider When Choosing an Industrial Panel PC:

Industrial PC offers a range of Panel PCs with varying display sizes and resolutions, touchscreen technologies, performance levels, connectivity options, environmental ratings, expansion options, reliability features, and manageability features. These systems are designed to provide reliable and high-performance computing in a compact and rugged form factor, making them ideal for use in industrial automation, process control, and monitoring applications.

THE LEADER IN INDUSTRIAL COMPUTING FOR 25 YEARS

Whether you are seeking a fanless embedded computer system, rugged touchscreen technology, high-performance industrial motherboards, or a reliable all-in-one PC solution for a harsh environment, you can rely on Industrial PC to deliver.

Whether you are seeking a fanless embedded computer system, rugged touchscreen technology, high-performance industrial motherboards, or a reliable all-in-one PC solution for a harsh environment, you can rely on Industrial PC to deliver.

Talk to an Expert

Talk to an Expert

Our experts have worked with top companies in some of the most demanding of industries including military, aerospace, heavy equipment, amusement parks, and industrial automation.

Call Us

(888) 255-5508

Email Us